-

Call Us

-

Email Us

sales@thebestcustomboxes.com

- Get A Quote

- Cart

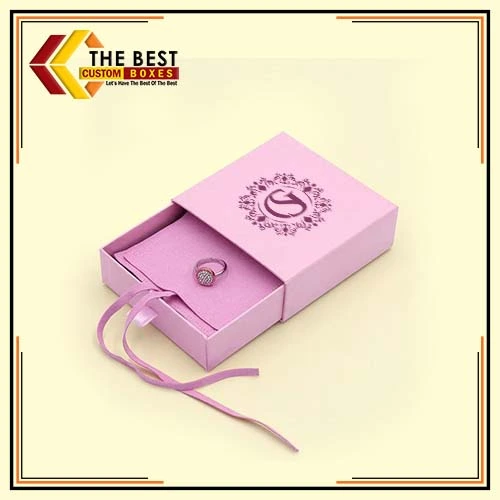

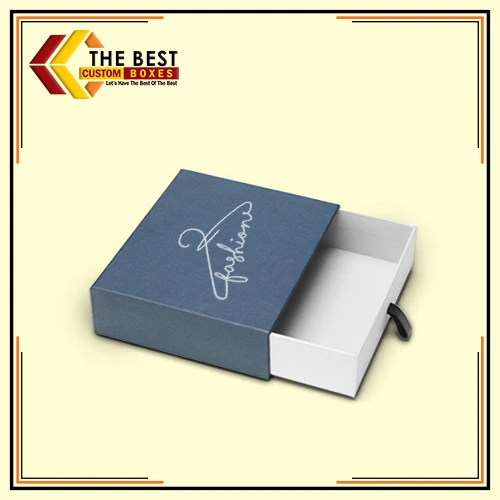

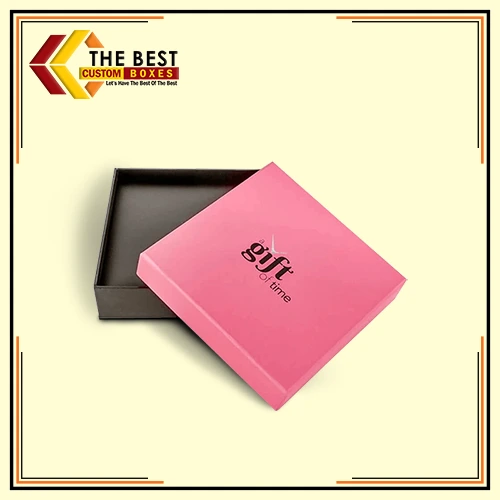

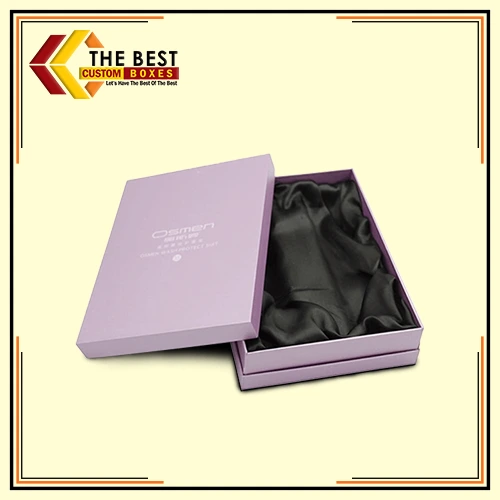

Printed Rigid Boxes

Printed rigid boxes give packaging a visual dimension by including bright images, writing, and graphics that add to the total appeal. These boxes are printed so logos, product information, and brand messages can be seen. They can be used for retail items, gifts, or promotional items. Printing makes the packaging look better, which makes it more attractive for customers to look at. Printed rigid boxes are flexible and can be used for many different goods. They are an excellent way to get brand identity and product details across.

Get A Quote

Quick Order

Price: $1.78

Box Style

Two Piece Style, Magnetic Closure, Drawer, Collapsible, Shoulder Neck

Dimension (L x W x H)

All Custom Sizes Available

Quantities

100 to 500000

Paper / Card Material

Rigid Material,

Printing

CMYK Colors,

PMS (Pantone Matching System),

Spot Colors,

Finishing

Gloss Lamination,

Matte Lamination,

Spot Gloss UV,

Foiling,

Included Options

Scoring,

Die Cutting,

Additional Options

Foil Stamping available in Gold, Silver, Copper, Red, Green, Rose Gold & Blue Color,

Proof

Flat View ,

3D Mock-up ,

Turnaround

Standard Production Plan:

The production time for Rigid Boxes normally takes 20-22 business days for making and further 5 - 6 business days for the ground shipping to reach at your doorstep.

Expedite Production Plan:

The expedited turnaround time for Rigid Boxes may vary as per the order quantities and will be shared at the time of order.

,Shipping

Assembled,

Packed in Boxes,

UPS,

Fedex,

DHL,

Custom Printed Rigid Boxes For Your Business:

When it comes to packaging the first impressions count. Custom printed rigid boxes are the ideal choice for those to present their products professionally and securely. Designed with quality and longevity in mind these boxes improve the client experience and offer a touch of luxury to your business.

Let's see the advantages, features and applications of custom printed rigid boxes and how they may help your items stand out.

Why Should You Choose Custom Printed Rigid Boxes?

Rigid boxes are noted for their durability and attractive look. These boxes offer excellent protection and a premium feel whether you sell high end gadgets, soft things like glassware or even luxury fashion accessories.

1. Durability That Safeguards Your Products:

Rigid boxes are built of durable materials that provide excellent protection during shipping and handling. Their sturdy design makes sure that delicate or pricey objects remain secure and unharmed.

2. Custom Designs To Match Your Brand:

Custom rigid box printing allows you to produce packaging suited to your brand's style. Add your logo, select colours matching your company and choose finishes like embossing or foil stamping for a polished appearance.

3. An Unforgettable Unboxing Experience:

Customers prefer packaging that feels nice. Rigid box package printing can help you create an unforgettable unboxing experience for customers to feel cherished and appreciated.

Advantages of Custom Printed Rigid Boxes Wholesale:

Buying in bulk is an affordable option to improve your packaging strategy. Let us consider some of the advantages.

1. Affordable For Larger Orders:

Purchasing wholesale saves money while having enough boxes for your products.

2. Consistence Brand Appearance:

With large orders, each package will appear the same resulting in a consistent brand impression.

3. Quick Delivery:

Wholesale solutions enable organizations to save and plan for seasonal demands or huge orders.

If you are selling goods and purchasing custom printed rigid boxes wholesale it means that you are constantly prepared to amaze your clients with outstanding packaging.

Features of Print Rigid Boxes:

Why do print rigid boxes stand out? Let us take a deeper look at their features.

1. Customization Options:

You can customize your rigid boxes in size, shape, style and colour to meet your specifications. The possibilities are endless for luxury goods.

2. High-Quality Printing:

Custom rigid box printing allows you to create eye-catching, bright designs for your boxes. High-quality printing makes sure that your brand looks consistent and professional.

3. Eco-Friendly Materials:

Many of today's clients value sustainability. Many customized luxury rigid boxes are created from eco-friendly materials which helps your company stay ecologically responsible.

4. A Variety Of Finishes:

You can choose from matte, glossy or textured finishes to match your product. Ribbons or magnetic closures can also give a box a classy look.

How Businesses Use Custom Printed Rigid Boxes:

These boxes are more than just decorative they are also efficient. Here are some common uses.

1. Luxury Retail Packaging:

High end brands use custom luxury rigid boxes to highlight their products' rarity.

2. Gift Packaging:

From custom candle boxes to beautiful jewellery boxes, rigid packaging lends a personal touch to gifts.

3. Subscription Boxes:

Print rigid boxes are perfect for subscription based products since they are sturdy and visually eye catching.

4. Promotional Items:

Firms frequently use custom rigid box printing to make a memorable impression when giving promotional gifts to clients or workers.

Choosing the Right Packaging Partner:

When choosing a rigid box packaging printing service look for someone who uses high-quality materials, uses modern printing techniques and is dedicated to perfection. Look for companies like The Best Custom Boxes that understand the value of mixing functionality and beauty in packaging.

Why Choose The Best Custom Boxes For Rigid Packaging:

At The Best Custom Boxes we are committed to offering custom printed rigid boxes that are ideal for your brand's demands. Our staff collaborates with you to provide customized solutions that represent your company's identity.

1. Bespoke Designs:

Each box is tailored to your brand's style and vision.

2. Best Quality Material:

We use long-lasting and environmentally friendly materials to preserve your products.

3. Fast Delivery:

We focus on your deadlines and provide speedy turnaround times to fulfill your business requirements.

Conclusion:

Custom printed rigid boxes are an excellent method of preserving your products while elevating your brand image. With limitless design options and unrivalled durability these boxes are an excellent solution for organizations seeking to make a lasting impression. Whether you are packing luxury goods, fragile items or promotional presents rigid boxes are a high-quality solution that reflects well on your business.

At The Best Bespoke Boxes, we are committed to offering high-quality, bespoke packaging solutions personalized to your specifications. Our boxes not only protect your products but also provide an excellent client experience.