-

Call Us

-

Email Us

sales@thebestcustomboxes.com

- Get A Quote

- Cart

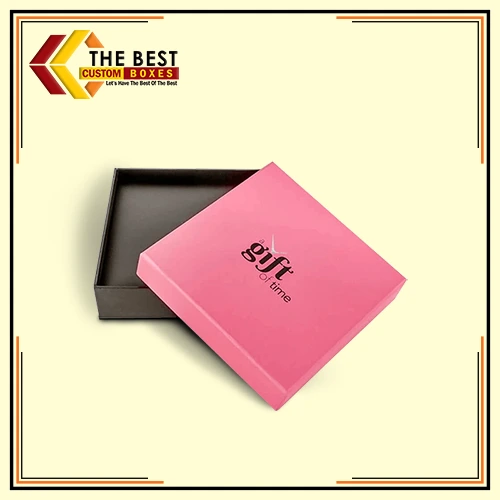

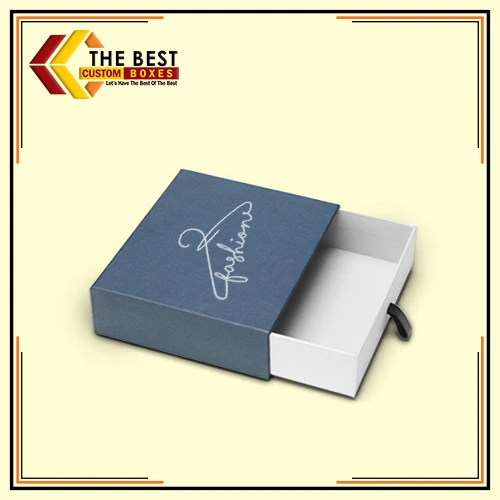

Rigid Chocolate Boxes

To beautifully protect delicate chocolates, Rigid Chocolate Boxes are an excellent packaging option. Because they are made of strong materials, these boxes keep the candies in perfect condition while they are being shipped. The hard structure gives them a touch of class, which makes them perfect for high-end chocolate brands that want to make an impact that lasts.

Get A Quote

Quick Order

Price: $4.51

Box Style

Two Piece Style, Magnetic Closure, Drawer, Collapsible, Shoulder Neck

Dimension (L x W x H)

All Custom Sizes Available

Quantities

100 to 500000

Paper / Card Material

Rigid Material,

Printing

CMYK Colors,

PMS (Pantone Matching System),

Spot Colors,

Finishing

Gloss Lamination,

Matte Lamination,

Spot Gloss UV,

Foiling,

Included Options

Scoring,

Die Cutting,

Additional Options

Foil Stamping available in Gold, Silver, Copper, Red, Green, Rose Gold & Blue Color,

Proof

Flat View ,

3D Mock-up ,

Turnaround

Standard Production Plan:

The production time for Rigid Boxes normally takes 20-22 business days for making and further 5 - 6 business days for the ground shipping to reach at your doorstep.

Expedite Production Plan:

The expedited turnaround time for Rigid Boxes may vary as per the order quantities and will be shared at the time of order.

,Shipping

Assembled,

Packed in Boxes,

UPS,

Fedex,

DHL,

Rigid Chocolate Boxes For Packaging Solution:

Regarding quality chocolates presentation is just as important as the flavor. Here is when rigid chocolate boxes come into play. These robust and attractive packaging solutions safeguard precarious gifts while providing a pleasant unwrapping experience. The Best Custom Boxes specializes in quality packaging that meets your chocolate storage and gifting needs.

Why Should You Use Rigid Chocolate Boxes?

Chocolates are delicate and they demand packaging that protects them while make them appear exceptional. Rigid chocolate boxes are built of a vital, robust substance that prevents chocolate from breaking or melting. These boxes also improve the presentation of your product, making it ideal for gifting or premium retail displays.

Businesses in the United States rely on The Best Custom Boxes to design useful and stylish packaging. We use advanced techniques to make sure that each box fulfills your expectations.

What Are The Most Popular Features of Custom Rigid Chocolate Boxes?

Here are some elements that businesses frequently include in their custom rigid chocolate boxes to provide value and functionality.

1. Magnetic Closures:

Magnetic closures provide refinement while keeping the box securely closed.

2. Embossing And Foil Stamping:

Embossing and foil stamping give the packaging a premium finish while also providing texture and visual intrigue.

3. Transparent Windows:

Perfect for displaying your chocolates, these windows give clients a glimpse of the high quality inside.

4. Compartments:

Custom inserts can be added to hold chocolates in place during shipment, preventing them from shifting and maintaining an attractive display.

These characteristics not only make the package more useful but they also improve the unboxing experience for customers.

What Are the Benefits of Using the Best Rigid Chocolate Boxes?

Here are some Benefits of Using the Best Rigid Chocolate Boxes:

1. Exceptional Durability:

Chocolate can be fragile. Our best rigid boxes for chocolates provide excellent protection, guaranteeing that your delicious gifts arrive in perfect condition, even throughout travel.

2. Customized Designs for Unique Branding:

We create each box to suit your brand's identity. From exquisite patterns to embossed logos, our packaging alternatives help your business stand out.

3. Eco-Friendly Materials:

Sustainability is important to your customers. That is why we use eco-friendly materials without sacrificing quality or design.

How Do Chocolate Rigid Boxes Improve Gifting?

Gifting is all about providing the great experience and the packaging provides the first impression. A wonderfully designed chocolate rigid box elevates your chocolates, making them feel like an expensive gift rather than a simple pleasure.

For organizations in the United States, our custom solutions ensure that your packaging matches the occasion, whether for Valentine's Day, corporate presents, or holiday specials.

What Is Special About Our Process?

The Best Custom Boxes follows a systematic process to ensure your packaging is perfect:

1. Understanding Your Needs:

We begin by learning about your product, target audience, and branding goals. This allows us to build designs that precisely match your needs.

2. Design Precision:

We use modern technology to carefully design your products. Every element is meticulously examined, from creating custom rigid gift boxes to including magnetic closures.

3. Fast Turnaround and Delivery:

We understand that timing is critical for your business. That's why we focus on speedy production and delivery throughout the United States.

How Does Our Packaging Benefit Businesses in The United States?

Here are some points:

• Boost Brand Identity:

Premium packaging, such as wholesale chocolate boxes, helps firms establish a powerful and memorable brand presence.

• Improves the Customer Experience:

A well-designed box preserves your chocolates while also making your clients feel treasured.

• Enhances Product Value:

Packaging influences perceived value. Luxurious chocolate boxes packaging options can boost your product's attractiveness and price.

Conclusion:

Regarding high-quality rigid chocolate boxes, The Best Custom Boxes is your reliable partner in the United States. Our long-lasting, elegant, personalized solutions ensure your chocolates look and taste great. Whether you're looking for chocolate boxes wholesale choices or distinctive chocolate rigid boxes, we can help you stand out.

One of our most popular choices is custom magnetic closure boxes, which are functional and fashionable. These boxes are simple to open and close, providing an extra touch of elegance to your chocolates. They're ideal for making a lasting first impression.