Have you ever seen boxes shaped like animals or people? These are called die cut boxes and can be used for many kinds of purposes. You may be curious about what are diecut boxes and how they are manufactured. In this blog we will answer these inquiries and more. Stay tuned.

What Are Die Cut Boxes?

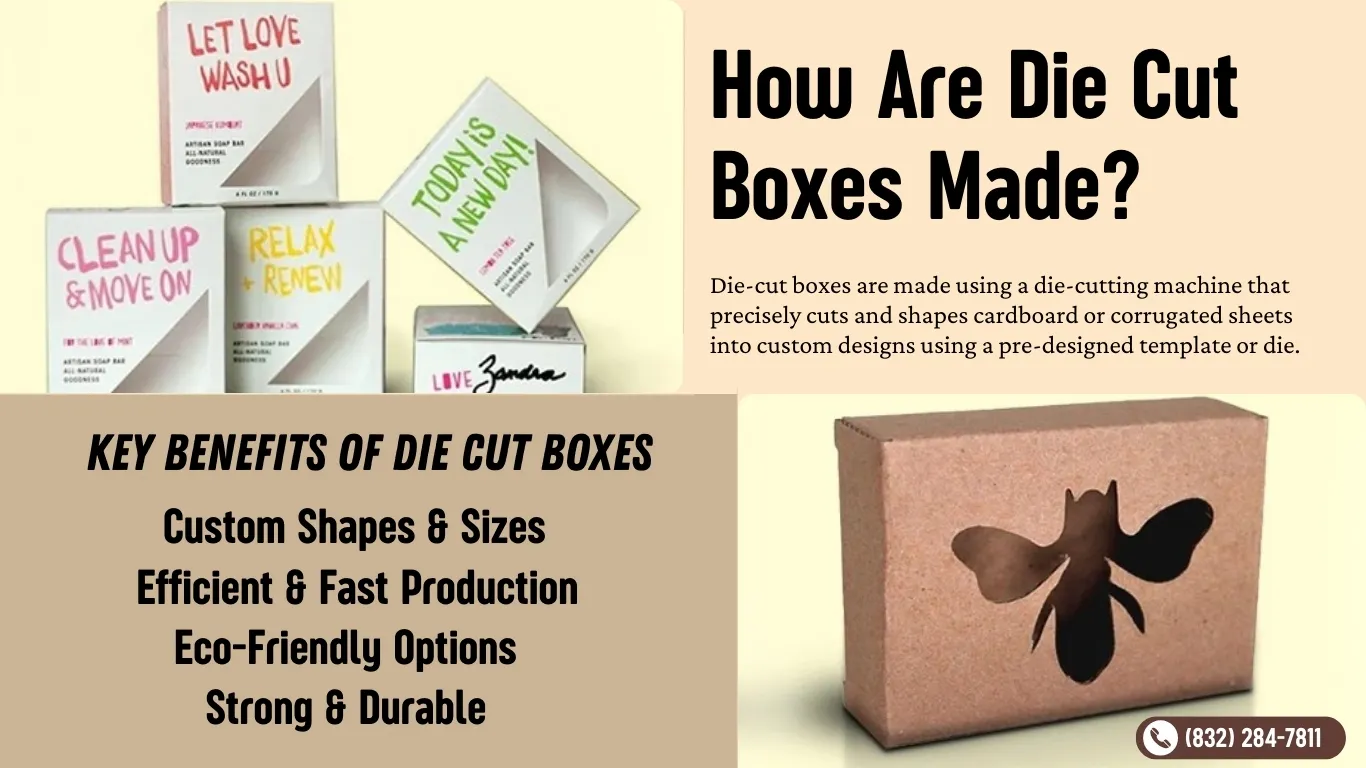

If you are looking for unique packaging you might have come across die cut boxes. But what are die cut boxes and why are they so popular? A die cuts them in certain forms. This is a sharp edged tool cuts materials like paper and cardboard. Die cutting is a popular method for creating customized product packaging.

Manufacturers commonly use die cutting boxes for soap, candles and small electronics. Designers can tailor them to fit the goods exactly and typically have a more premium appearance than a basic box.

In addition, die cut packaging can be visually appealing. Its distinct shapes typically set it apart from the crowd. If you want to make your product packaging stand out consider die cut custom folding boxes.

Why Are Die Cut Boxes Popular For Packaging?

Now the most asked question is Why are die cut boxes popular for packaging? There are a variety of reasons. First and foremost they provide an exact fit for products eliminating movement within the box and minimizing damage. Unlike standard boxes which require additional padding these boxes require less packaging materials.

Second they are customizable. Businesses can customize these boxes with logos, colors and designs that reflect their brand identity. This improves product presentation and provides a memorable unboxing experience for clients.

Another factor is cost effectiveness since manufacturers produce them from a single sheet. Thus there is less waste which lowers material costs. Furthermore their strong design promotes product safety resulting in fewer returns and replacements.

The Materials Use For Die Cut Packaging

Die-cut packaging has a unique and bespoke appearance but what materials are used for die cut packaging? Manufacturers make die cut packaging out of a range of materials based on the product’s specifications and industry standards. The most frequent materials are.

- Corrugated cardboard is strong and durable making it perfect for shipping and preserving fragile objects.

- Kraft paper is a popular choice for sustainable packaging because it is both eco friendly and recyclable.

- Paperboard is a lightweight but strong material retailer commonly use for retail packaging, cosmetics and minor consumer goods.

- The use of plastic and foam. In some circumstances die cut packaging may include plastic or foam inserts to cushion sensitive products.

How Do Manufacturers Make Die Cut Boxes?

Manufacturers use a machine to cut a material and score sheets of material into predetermined forms. The process includes:

1. Designing The Template:

The die cut box manufacturer creates a layout that corresponds to the product’s size and shape.

2. Creating the Die:

Manufacturers utilize sharp blades to create an unique die that accurately cuts and creases the material.

3. Cutting the Material:

The sheet presses against the die to create the desired shape.

4. Folding And Assembly:

After cutting fold the box along the creased lines and assemble.

This rigorous technique guarantees that each box has a consistent size and quality making it perfect for packing.

How to Select The Best Die Cut Box For Your Business?

When choosing die cut boxes for your business consider the following factors.

1. Product Dimensions:

Select a size that will accommodate your product without taking up too much space.

2. Material Strength:

Choose materials according to the fragility and weight of your items.

3. Customization Requirements:

Select branding components, colors and printing options.

4. Budget:

Compare prices from several manufacturers to discover the most cost effective alternative.

Where Can I Order?

If you want to know where can I order high-quality die cut boxes The Best Custom Boxes is a reliable choice. They develop quality custom packaging solutions based on corporate specifications. As a USA company they exclusively deliver within the country making sure prompt and effective service.

Customers trust The Best Custom Boxes for their attention to detail, long lasting materials and ability to develop unique packaging that boosts company identity. They offer exceptional customer service and cheap pricing for both trim and bulk orders.

Conclusion:

Theseboxes are a versatile and cost effective packaging option appropriate for a wide range of industries. Their ability to give a secure fit, flexible design and environmentally friendly materials make them a popular choice among enterprises. Businesses use these boxes for a variety of applications including shipping, retail and branding. If you are looking for quality die cut boxes think about The Best Custom Boxes a US based firm that provides dependable packaging solutions.

Now that you understand what are die cut boxes so you can make an informed decision about which packaging is perfect for your business.

FAQs

1. Are Die Cut Boxes Recyclable?

Yes most die cut boxes are made of recyclable materials like cardboard and kraft paper. Businesses searching for sustainable packaging might choose eco friendly materials.

2. Can I Get Folding Boxes In Various Shapes?

Yes custom folding boxes can be built in a variety of forms and sizes to meet specific product needs. Many manufacturers provide extensive customization choices.

3. How Long Does It Take To Manufacture Die Cut Boxes?

Production time varies based on order quantity and customization needs. Bulk orders often take between a few days and a number of weeks.

4. Where Can I Find a Die Cut Box Manufacturer?

Numerous die cut box manufacturers are accessible but if you are in the United States The Best Custom Boxes is a reliable source for high quality packaging solutions.